Premium Countertop Solutions for Private and Business Jets

Premium countertops in galleys and lavatories are far more than functional surfaces — they represent your commitment to uncompromising quality and attention to detail. These critical touchpoints directly influence passenger comfort, cabin hygiene, and the overall perception of luxury throughout your aircraft. AeroVisto transforms these essential surfaces with premium solid surface solutions that meet the expectations of discerning jet owners, innovative interior designers, and aviation professionals who demand perfection.

Beyond Aesthetics: Where Function Meets Sophistication

Aircraft countertops endure constant use, temperature variations, and the unique stresses of flight operations. When these surfaces begin showing wear — scratches, stains, or simply looking dated — they significantly lower the entire cabin experience. The right countertop solution can transform not just the appearance but the very functionality of your aircraft interior.

Premium solid surfaces like Corian® and Staron® combine the timeless elegance you expect with the advanced performance your aircraft demands. Their non-porous nature creates an inherently hygienic environment, resisting bacteria and moisture in ways traditional materials simply cannot match. This isn’t just about looking pristine; it’s about maintaining the highest standards of cleanliness in your cabin’s most critical areas.

The Strategic Advantage of Premium Solid Surfaces

Transform Your Cabin Experience

- Seamless Sophistication: Unlike traditional materials with visible joints, premium solid surfaces create flowing, uninterrupted surfaces that eliminate bacterial breeding grounds while delivering stunning visual continuity throughout your cabin.

- Optimal Performance: Every kilogram matters in aviation. Our premium solid surfaces offer an optimal weight-to-performance ratio, contributing to improved fuel efficiency without compromising on luxury or durability.

- Infinitely Renewable: Minor scratches and wear marks that would permanently mar other materials can be easily polished buffed away, keeping your surfaces looking factory-fresh for years. This renewability isn’t just convenient — it’s a game-changer for maintaining your aircraft’s value.

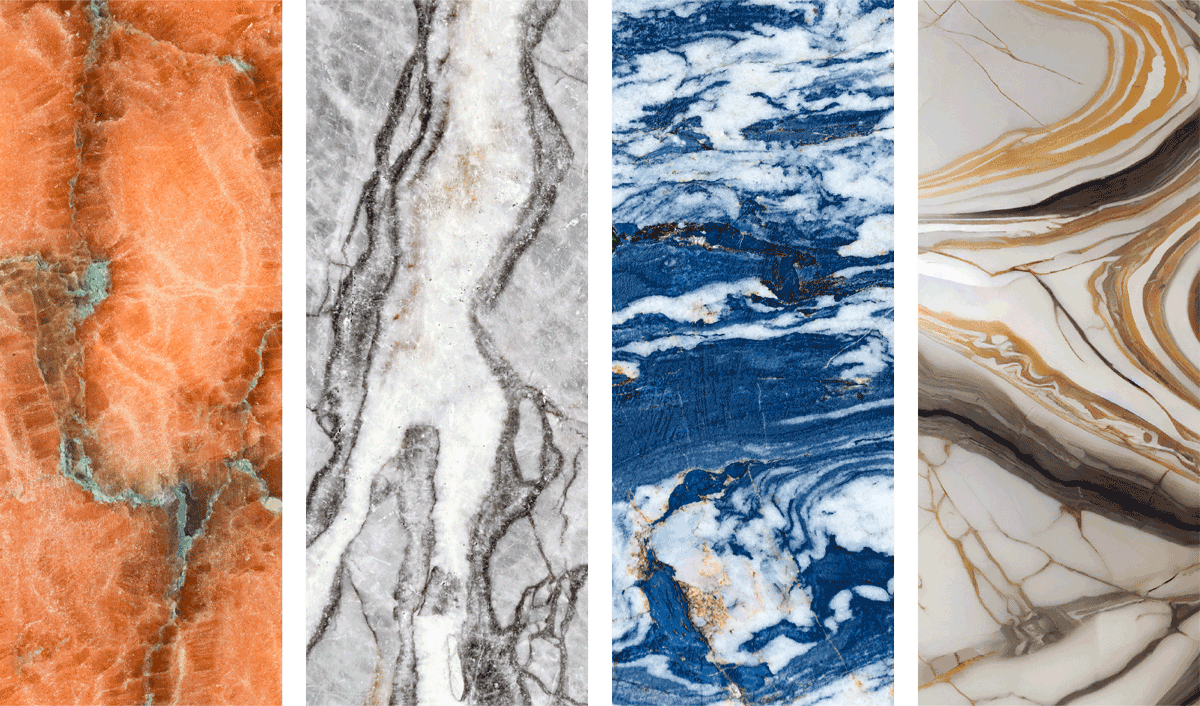

- Various Design Options: With over 150 color options and the ability to create custom curves and integrated features, these materials adapt to your vision, not the other way around. From seamless sinks to backlit accents, the possibilities are truly limitless.

- Temperature Resilient: Engineered to withstand the extreme temperature variations of flight operations, without cracking, warping, or losing their lustrous finish.

When Premium Materials Make All the Difference

The Hidden Costs of Compromise

Choosing the wrong countertop material isn’t just an aesthetic misstep. What might appear as cost savings initially often transforms into a cascade of expenses, inefficiencies, and compromises that no discerning aircraft owner should accept.

Consider the Real Impact:

Every time you or your passengers encounter a scratched, stained, or worn countertop, it sends a message. In chartered aircraft, this directly affects your ability to command premium rates. For private owners, it reduces the satisfaction and delight of ownership. But the implications run far deeper than mere appearances.

The Maintenance Trap

Natural stone requires regular sealing. Laminate edges can delaminate in the temperature extremes of flight operations. Each of these maintenance requirements means more than just cost — it means downtime. Your aircraft sitting in a hangar for repairs is an aircraft that isn’t flying, isn’t earning, and isn’t serving its purpose.

Safety and Certification Complexities

Not all materials meet aviation’s stringent safety standards without modification. Some require special treatments or additional certifications that complicate installation and increase costs. Others may pass initial tests but degrade over time, potentially compromising their fire-resistant properties. With premium solid surfaces specifically engineered for aviation, these concerns don’t exist.

The Passenger Experience Factor

A countertop with visible seams becomes a collection point for spills and bacteria. A surface that shows water spots or fingerprints requires constant attention from crew members. These seemingly minor issues accumulate into a lowered experience, reflecting your operation’s overall quality.

Replacement vs. Renewal Perhaps most critically, traditional materials often require complete replacement when damaged. A deep scratch in laminate or a crack in natural stone typically means starting over. Premium solid surfaces, by contrast, can be renewed repeatedly through simple buffing and sanding, extending their life indefinitely and protecting your investment.

When comparing countertop materials for your business jet, the differences become clear:

| Feature | Premium Solid Surface (Corian, Staron) | Natural Stone (Marble, Quartz) | Laminate | Wood Veneer |

|---|---|---|---|---|

| Weight (relative) | Optimal weight-to-performance ratio | Heavy | Lightweight | Lightweight |

| Durability | Superior durability against impacts/scratches | Highly durable but marble susceptible to etching | Less durable; susceptible to chipping/cracking | Thin layer can chip/peel |

| Hygiene | Non-porous; resists bacteria, mold, stains | Porous (marble/limestone); requires sealing | Non-porous surface, but delamination creates issues | Can be water-resistant; requires sealing |

| Maintenance | Simple to clean; no sealing required | Requires regular sealing & pH-neutral cleaners | Easy to clean initially | Requires clear coat protectant |

| Heat Resistance | Good, but use trivets for extreme heat | Highly heat-resistant | Limited; susceptible to burns/discoloration | Can be vulnerable to heat damage |

| Repairability | Easily repairable (sanding/buffing) | Challenging; often professional attention needed | Not repairable; requires full replacement | Challenging; not refinishable |

| Design Flexibility | Extensive colors, seamless, thermoformable | Unique patterns, but limited shaping | Wide patterns, but visible seams | Wide variety but limited integration |

| Aviation Compliance | Specifically engineered for aviation standards | Requires verification | Challenges with flammability/smoke/toxicity | Requires verification |

Stone Countertops — For Those Who Love the Exceptional

In private aviation, excellence is not just a benchmark — it’s a personal commitment. For some aircraft owners, that commitment includes a bold design choice: countertops made from solid stone.

At AeroVisto, we understand this aspiration. A stone countertop is never just a surface — it’s a statement. It reflects a passion for timeless aesthetics, a dedication to craftsmanship, and the ambition to elevate every detail of the cabin experience. It’s where personal vision meets engineered precision and individuality takes shape.

Solid Stone. Seamlessly Integrated.

Stone countertops are rare in aircraft interiors — for good reason. Their integration requires precise engineering, custom reinforcement, and a deep understanding of aviation requirements. And that’s precisely what we offer.

AeroVisto has the capability and skills to realize stone countertop installations that are as durable and safe as they are visually striking. Whether marble, granite, or engineered alternatives — our teams analyze each project individually, adapt the structure accordingly, and guide the certification process from start to finish.

If you choose stone, you choose a signature element. With AeroVisto, that choice is in the best hands. We ensure that your countertop is not only a visual centerpiece but also a structurally sound, fully certified component of your cabin.

From fit and finish to long-term durability, we handle every step — so you can enjoy your countertop as a lasting part of your aircraft’s identity.

Let's explore how we can bring your vision to life — boldly, beautifully, and without compromise.

The AeroVisto Advantage: Precision Meets Passion

Expert Craftsmanship for Demanding Standards

At AeroVisto, we understand that generic countertop solutions have no place in business aviation. Our specialized approach includes:

- Meticulous Digital Templating: Using state-of-the-art laser technology to capture every nuance of your aircraft’s unique geometry

- Precision CNC Fabrication: Advanced machinery ensures perfect fit and flawless finish

- Aviation-Certified Installation: Our technicians bring decades of experience specific to aircraft interiors

- Seamless Integration: Careful attention to interfaces with existing cabin components ensures both beauty and structural integrity

Compliance Without Compromise

As a certified EASA Part 145 Maintenance Organization, Part 21G Production Organization, and UK.145 Maintenance Organisation, AeroVisto handles all regulatory requirements seamlessly across both European and UK jurisdictions. Our premium solid surfaces meet stringent FAR 25.853 fire safety standards, including vertical burn, smoke density, and heat release requirements. We manage all documentation — from Engineering Orders and STCs to Major/Minor Change Certifications, EASA Form 1, and UK Certificates of Release to Service. Our expertise includes complete coordination with approved EASA 21J Design Organizations, flammability sampling and testing, ensuring your project proceeds smoothly without regulatory delays regardless of your aircraft’s registration or operating requirements.

Comprehensive Interior Solutions

Your countertop project seamlessly integrates with our full range of interior services:

- Premium Upholstery Solutions to refresh your seating

- Veneering and Varnishing Services for cohesive cabin aesthetics

- Window Assembly Modifications to complete your interior transformation

- Aircraft Carpet Replacement for total cabin harmony

Environmental Excellence

AeroVisto’s commitment to sustainability extends to our countertop solutions. We work exclusively with manufacturers who demonstrate environmental responsibility, ensuring your luxury doesn’t come at the cost of our planet’s future. Our premium materials are engineered for longevity, reducing waste through extended service life and repairability.

Transform Your Aircraft Interior Today

Whether you’re planning a complete galley refresh, upgrading lavatory surfaces, or reimagining your entire cabin, AeroVisto’s premium countertop solutions deliver the perfect blend of luxury, performance, and value. Our One-Stop-Shop approach means you work with a single trusted partner who understands every aspect of business jet interiors.

Get Your Quote — Premium Countertop Solutions

AeroVisto Interior Services AG is a certified Part 145 EASA Maintenance Organization and a Part 21G EASA Production Organization and delivers the needed documentation with every service. This includes the Engineering Order, STC, Major Change, Minor Change Certification, and EASA Form 1. We take care of the complete coordination of the certification, including flammability sampling and testing and interaction between our production engineering and the corresponding team of the approved EASA 21J Design Organization.