film application on Bombardier Global 5000 – take a look

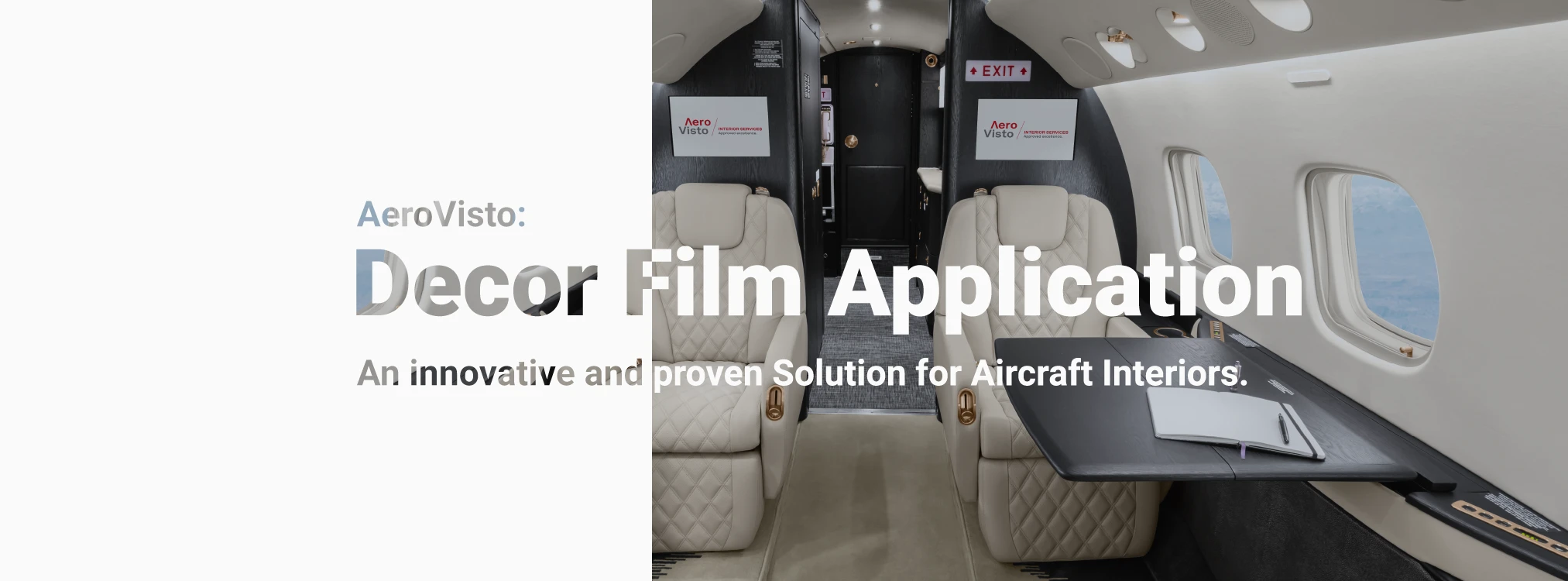

Decor Film Application

An innovative and proven Solution for Aircraft Interiors.

As an EASA-approved aviation interior specialist, we are pioneers in offering customer-centric interior refurbishment solutions. For more than five years now, AeroVisto has been offering Decor Film Application as an innovative new choice and alternative to traditional refurbishment options. With its compelling benefits, Decor Film Application is highly successful with aircraft operators, cost-conscious aircraft owners, and aircraft in transition. AeroVisto‘s unrivaled expertise in this technique allows us to offer our clients a 5-year warranty

Benefits at a glance

less weight

less downtime

easy on budget

high quality and durable

unlimited design freedom

easy to clean, maintain & repair

Get your sample

We provide customers the opportunity to request samples, enabling them to evaluate our product quality. Explore a broad range of patterns and colors to experience the durability and texture of our Decor Film Applications firsthand. Click the button below to get your samples.

Yes, send me my samples ...

What our clients say:

What sets AeroVisto apart is not just their role as pioneers in this field. Even as other providers and OEMs have begun offering similar solutions, AeroVisto maintains its leadership position through superior quality, material expertise, and execution durability. Their commitment to innovation and problem-solving is remarkable — where others might have hesitated, Hermann Bauer and his team, with colossal engagement, delivered practical solutions that met our needs.

After all, we are still convinced of this Solution. The ability to perform quick repairs remains one of the key advantages, making it invaluable for our operations. AeroVisto didn't just provide a service; they initiated a new approach to cabin refurbishment that has transformed how we maintain our fleet's interiors."

One of the standout features of this interior, mainly driven by budget, was the application of a decorative 3M film over the existing wood veneer and hardwood edges.

AeroVisto brought their extensive experience to the project, meticulously applying the film to replicate the natural grain direction of real wood. This attention to detail ensured an authentic and seamless appearance throughout the cabin.

One of the key benefits of this technique is its practicality: if the film is damaged, the local affected area can be easily repaired without removing the cabinetry from the aircraft. From a design perspective, the 3M film offers a wide range of options, with various imitation wood grains and textures to choose from.

To ensure durability, the edges of the film were carefully secured to prevent peeling, and a protective ceramic finish was applied to enhance longevity and performance.

High quality look

and feel on attractive terms.

The atmosphere of a business jet is significantly influenced by its interior. From elegant wood finishes to modern carbon designs, the interior mirrors the high expectations of both owners and passengers for a private aircraft. However, even premium materials show wear over time, and business jet interiors can lose their initial luster, particularly in aircraft frequently used by charter companies. When it’s time for an interior refurbishment, a key question arises: how to address the numerous interior surfaces—cabinets, doors, panels, covers, and even pull-out and conference tables. With unlimited time and budget, existing surfaces can be intricately varnished, polished, or entirely re-veneered. Yet, this isn’t always feasible, not just due to high costs but also the extensive time required for such refurbishments. Decor Film Application emerges as the ideal solution in these scenarios, offering a swift, cost-effective, and high-quality alternative to traditional refurbishment methods.

film application on the Embraer Legacy 600 – take a look

film application on Embraer Legacy 600 – take a look

High Durability and Extensive Design Options.

Our professional film applications present a compelling alternative to traditional veneering and painting of jet interior surfaces. They not only shorten the refurbishment period, reducing aircraft downtime, but also excel in durability for daily flight operations, alongside offering a wide array of design choices with modern materials. However, opting for film applications necessitates choosing an experienced professional to ensure the premium results that aircraft owners and passengers rightfully anticipate from a business jet interior.

Cost-Effective Solution to Veneering and Painting

Decor Film Applications provide a visually appealing and valuable upgrade for old or worn surfaces. Unlike the more time-consuming processes of re-veneering or repainting, film application can cut the interior refurbishment duration of an aircraft by at least 50%, while also being considerably more affordable. This makes film applications especially appealing for projects where time and budget are key considerations. Beyond the attractive pricing, film applications offer superior maintainability compared to all other alternatives.

Do it, but Do it right!

The AeroVisto Difference in Decor Film Application

While many providers attempt to offer decor film application for aircraft interiors, few truly understand the complexities of this service in aviation. At AeroVisto, we’ve developed unique techniques that go beyond standard practices, ensuring that when we do it, we do it right.

At AeroVisto, “Do it, but Do it right!” isn’t just a slogan—it’s our commitment to excellence in every project. Our distinctive approach encompasses four key areas that set us apart in aviation decor film application:

1. Technical Excellence in Aviation

Our application technique is specifically engineered for aviation’s unique demands:

- Advanced methods designed to withstand extreme in-flight conditions

- Proven performance through temperature fluctuations and pressure changes

- Precision that exceeds industry standards with perfection visible up close

- Stress-resistant application preventing delamination in temperatures from -30°C to +80°C

- Enhanced durability to withstand the rigors of frequent flight operations

- Meticulous attention to every detail, from cabinet gaps to drawer operations

2. Preparation Excellence

A flawless finish starts with meticulous preparation—a step we never compromise on:

- Comprehensive surface preparation ensuring exceptional longevity

- Enhanced bonding strength preventing premature delamination

- Imperfection elimination resulting in a sleek, professional finish

- Optimized adhesion through thorough surface cleaning and treatment

- Precision sanding with careful attention to gaps and fittings

- Strict environmental control maintaining optimal temperature and humidity throughout the process

3. Wood Grain Mastery

Our expertise in wood grain application elevates decor film to an art form:

- Authentic grain patterns that meticulously recreate natural wood appearance

- Precise miter joints ensuring seamless transitions at corners

- Advanced techniques creating genuine depth and tactile texture

- Expert color matching replicating specific wood types with striking accuracy

- Consistent grain flow maintained across different panels and surfaces

- Final results that rival the beauty of natural wood veneer

4. Aircraft-Specific Expertise

Our extensive experience across aircraft types enhances every project:

- Efficient handling of model-specific disassembly and reassembly

- Proactive identification and resolution of potential challenges

- Optimized scheduling based on detailed knowledge of each aircraft type

- Special attention to model-specific sensitive areas and components

- Comprehensive expertise covering major manufacturers including Bombardier, Embraer, Cessna, Gulfstream, and more

- Time-efficient processes based on deep understanding of each aircraft model

Each of these elements contributes to our uncompromising standard of quality. While others might take shortcuts, our commitment to “doing it right” means delivering exceptional results that stand the test of time and the demanding conditions of aviation service.

Get Your Solution Guide

In recent years, AeroVisto has invested much expertise and energy in developing new and innovative aircraft cabin solutions. We have summarized the most helpful information about our solutions and your numerous refurbishment options solutions in handy solution guides. Don’t hesitate to contact our sales team, we will gladly provide them to you.

Yes, send me the Solution Guide about ...

AeroVisto Interior Services AG is a certified Part 145 EASA Maintenance Organization and a Part 21G EASA Production Organization and delivers the needed documentation with every service. This includes the Engineering Order, STC, Major Change, Minor Change Certification, and EASA Form 1. We take care of the complete coordination of the certification, including flammability sampling and testing and interaction between our production engineering and the corresponding team of the approved EASA 21J Design Organization.